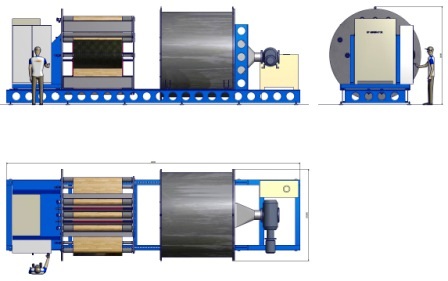

SNC R2R – vacuum roll-to-roll machine with magnetron sputtering of ultrathin metal/metal oxide antiviral and antibacterial coatings on nonwoven with oxygen flow control by feedback of plasma emission spectroscopy.

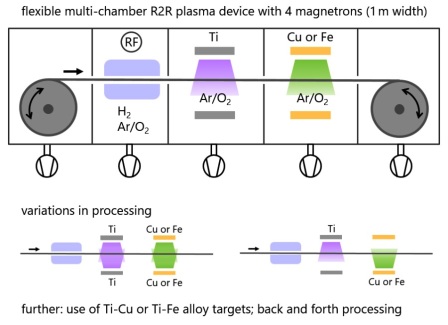

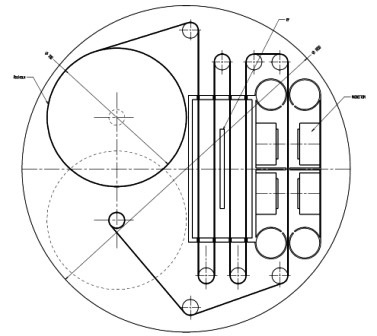

The hierarchical textile structure supports the formation of a large number of catalytically active metal sites. A low pressure plasma R2R process for coatings on nonwovens is involving plasma pretreatment and subsequent sputtering from Ti and Cu or Fe targets considering reactive sputtering with different O2/Ar ratios in a one-step process to produce large areas of dissimilar metal interfaces. Nonwoven material, used for barrier masks and air filterer, having porous structure possesses a large surface area where bacteria and viruses can stick, thus demanding surface treatments to reduce the risk of infections. In order to stop viruses and bacteria proliferation on the surface of nonwoven material we deposit non-leaching metal/metal oxide coatings in vacuum that are active by Reactive Oxygen Species (ROS) formation close to the surface yielding contact killing of viruses as well as bacteria. Catalytically active metal/metal oxide coatings enable efficient ROS formation at their interface. ROS as produced by visible light stimulation (photoinduced) or in the dark (at oxygen vacancies) enable fast contact killing of microorganisms. Cu and Fe nanostructures deposited on TiO2 supports are among the most efficient metal/metal oxide combinations to produce ROS New coating process generates large metal/metal oxide interface areas by depositing adjusted amounts of Cu and Fe on ultrathin TiO2 supports by magnetron sputtering. Besides the use of anatase TiO2 supports, an increased number of oxygen vacancies enabled by adjusting sputter conditions enhance hole transfer and water dissociation to produce ROS even under dark conditions improving the efficacy of the antiviral surface.

Copyright © 2013 NCI - Swissnanocoat SA 515048